Supercritical Foaming Light and High Elastic MTPU

Parameters

| Item | Supercritical Foaming Light and High Elastic TPEE |

| Style No. | FW12T |

| Material | TPEE |

| Color | Can be customized |

| Logo | Can be customized |

| Unit | Sheet |

| Package | OPP bag/ carton/ As required |

| Certificate | ISO9001/ BSCI/ SGS/ GRS |

| Density | 0.12D to 0.16D |

| Thickness | 1-100 mm |

What’s Supercritical Foaming

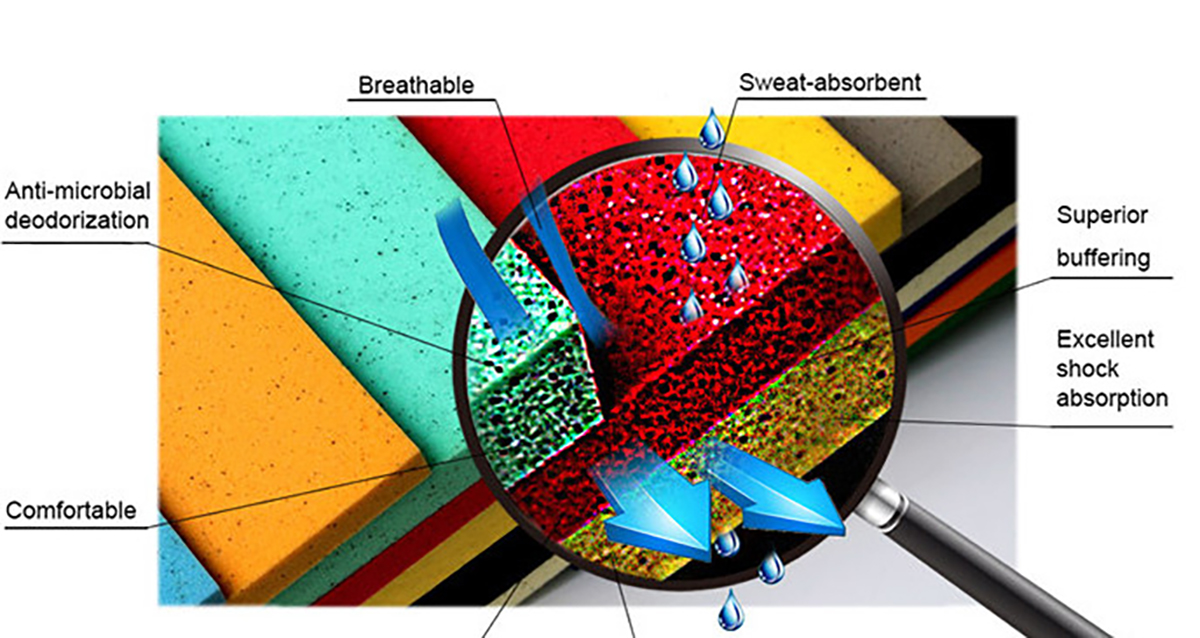

Known as Chemical-Free Foaming or physical foaming, this process combines CO2 or Nitrogen with polymers to create a foam, no compounds are created and no chemical additives are required. eliminating toxic or hazardous chemicals typically used in the foaming process. This minimizes environmental risks during production and results in a non-toxic end product.

FAQ

Q1. Which industries can benefit from Foamwell technology?

A: Foamwell technology can benefit numerous industries including footwear, sports equipment, furniture, medical devices, automotive and more. Its versatility and superior performance make it ideal for manufacturers looking for innovative solutions to enhance their products.

Q2. In which countries does Foamwell have production facilities?

A: Foamwell has production facilities in China, Vietnam and Indonesia.

Q3. What materials are mainly used in Foamwell?

A: Foamwell specializes in the development and manufacture of PU foam, memory foam, patented Polylite elastic foam and polymer latex. It also covers materials such as EVA, PU, LATEX, TPE, PORON and POLYLITE.

Q4. What types of insoles does Foamwell offer?

A: Foamwell offers a variety of insoles, including supercritical foam insoles, PU orthopedic insoles, custom insoles, height increasing insoles and high-tech insoles. These insoles are available for different foot care needs.