Supercritical Foaming Light and High Elastic MTPU

Parameters

| Item | Supercritical Foaming Light and High Elastic MTPU |

| Style No. | FW12M |

| Material | MTPU |

| Color | Can be customized |

| Logo | Can be customized |

| Unit | Sheet |

| Package | OPP bag/ carton/ As required |

| Certificate | ISO9001/ BSCI/ SGS/ GRS |

| Density | 0.12D to 0.2D |

| Thickness | 1-100 mm |

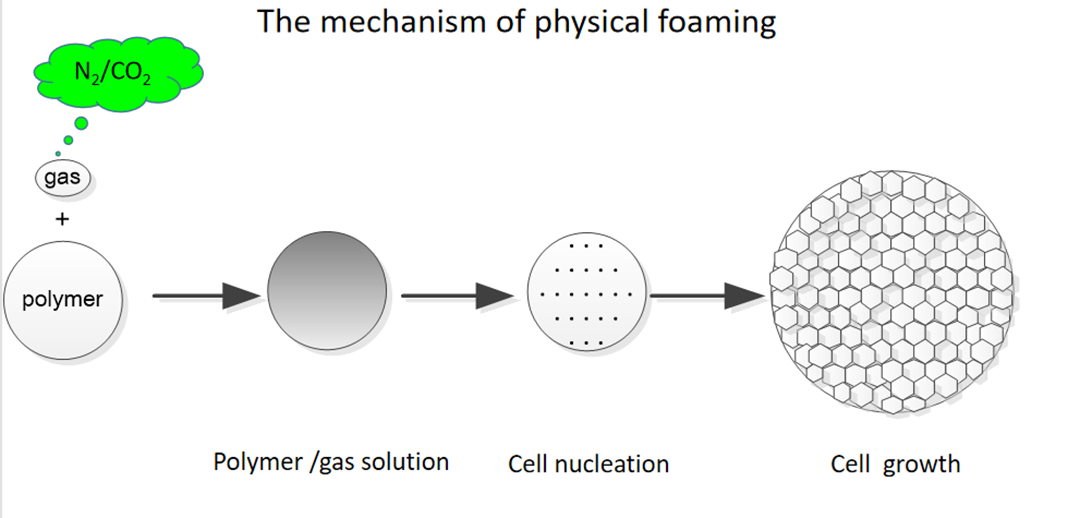

What’s Supercritical Foaming

Known as Chemical-Free Foaming or physical foaming, this process combines CO2 or Nitrogen with polymers to create a foam, no compounds are created and no chemical additives are required. eliminating toxic or hazardous chemicals typically used in the foaming process. This minimizes environmental risks during production and results in a non-toxic end product.

FAQ

Q1. Are the insoles made of environmentally friendly materials?

A: Yes, the company offers the option to use recycled or bio-based PU and bio-based foam which are more environmentally friendly alternatives.

Q2. Can I request a specific combination of materials for my insoles?

A: Yes, you can request a specific combination of materials for your insoles to meet your desired comfort, support and performance requirements.

Q3. How long does it take to manufacture and receive custom insoles?

A: Manufacturing and delivery times for custom insoles may vary depending on specific requirements and quantities. It is best to contact the company directly for an estimated timeline.

Q4. How is your product/service quality?

A: We pride ourselves on delivering quality products/services of the highest standards. We have an in-house laboratory to ensure our insoles are durable, comfortable and fit for purpose.

Q5. How to ensure the durability of the insole?

A: We have an in-house laboratory where we conduct rigorous testing to ensure the durability of the insoles. This includes testing them for wear, flexibility and overall performance.