Supercritical Foaming Light and High Elastic PEBA

Parameters

| Item | Supercritical Foaming Light and High Elastic PEBA |

| Style No. | FW07P |

| Material | PEBA |

| Color | Can be customized |

| Logo | Can be customized |

| Unit | Sheet |

| Package | OPP bag/ carton/ As required |

| Certificate | ISO9001/ BSCI/ SGS/ GRS |

| Density | 0.07D to 0.08D |

| Thickness | 1-100 mm |

What’s Supercritical Foaming

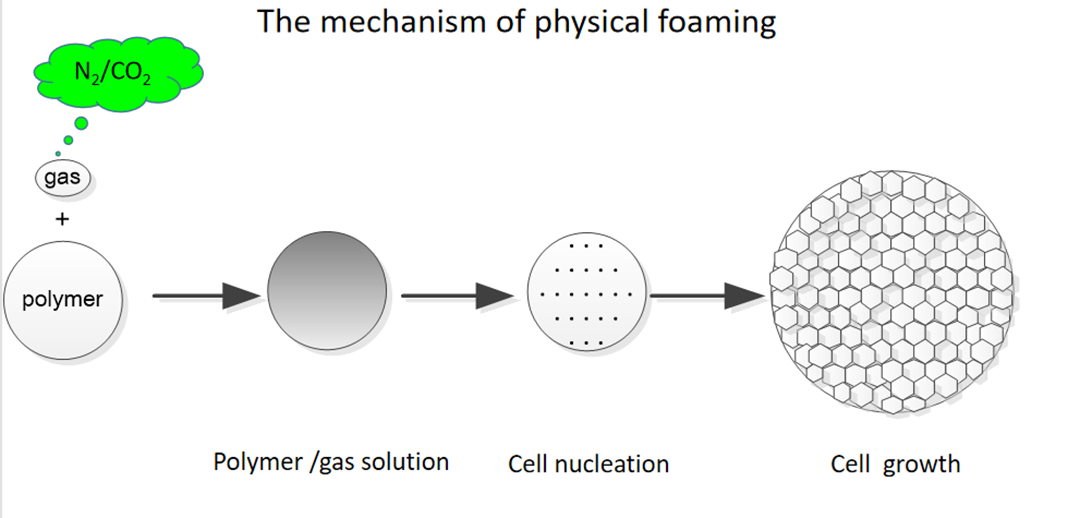

Known as Chemical-Free Foaming or physical foaming, this process combines CO2 or Nitrogen with polymers to create a foam, no compounds are created and no chemical additives are required. eliminating toxic or hazardous chemicals typically used in the foaming process. This minimizes environmental risks during production and results in a non-toxic end product.

FAQ

Q1. How is the company's experience in insole manufacturing?

A: The company has 17 years of insole manufacturing experience.

Q2. What materials are available for the insole surface?

A: The company offers a variety of top layer material options including mesh, jersey, velvet, suede, microfiber and wool.

Q3. Can the base layer be customized?

A: Yes, the base layer can be customized to your exact needs. Options include EVA, PU foam, ETPU, memory foam, recycled or bio-based PU.

Q4. Are there different substrates to choose from?

A: Yes, the company offers different insole substrates including EVA, PU, PORON, bio-based foam and supercritical foam.

Q5. Can I choose different materials for different layers of the insole?

A: Yes, you have the flexibility to choose different top, bottom and arch support materials according to your preferences and requirements.